This report analyzes the global roll-to-roll technology for flexible device market in terms of mechanism, application, and geography. On the basis of mechanism employed, the global roll-to-roll technology for flexible device market is segmented into gravure, flatbed and rotary screen printing, flexographic printing, imprint lithography, laser ablation, offset printing, inkjet printing, and other mechanisms. Similarly, based on application, the global roll-to-roll technology for flexible device market is classified into consumer electronics, automotive, energy, healthcare, and defense and security among others. The geographical distribution of the global roll-to-roll technology for flexible device market considered in this study encompasses regional markets such as North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

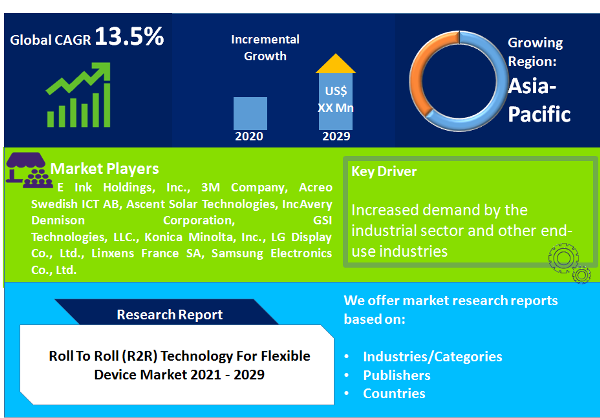

Growing desire among flexible device manufacturers to curb manufacturing cost in order to sustain profit margins and better penetrate markets is expected to drive adoption of roll-to-roll manufacturing technologies/techniques during the forecast period. In addition, since R2R processing consume less energy and have comparatively higher throughput capacity than traditional manufacturing processes, their adoption among flexible device manufacturers is bound to grow in the coming years. However, lack of primary standardized infrastructure at most manufacturing facilities and lack of awareness regarding the potential and limitations of roll-to-roll processes has hampered the adoption of roll-to-roll technologies among manufacturers.

Consumer electronics represents the largest application segment for the flexible device roll-to-roll technology market. The segment accounted for 68.2% of the global market revenue in the base year 2021. The trend shall prolong and the segment is presumed to retain its leading position, exhibiting strong growth through forecast period 2025 – 2033. Roll-to-toll technology is predominantly used to manufacture flexible and printed circuits. The demand for flexible printed circuits is witnessing an upsurge, replacing conventional circuit boards on account of growing preference for miniaturization and superior functionality in consumer electronics. In addition, flexible printed circuits consume less space and reduce weight of electronic devices making them preferable to be used in wearable electronics, and touch screen devices like smartphones and tablets. This, in turn has a positive impact on the overall demand for R2R processing equipment that have proved cost effective for manufacturing flexible circuit devices.

As of 2021, flatbed and rotary screen printing was the preferred mechanism used for roll-to-roll manufacturing across the globe. The segment accounted for around one-fourth of the global market revenue in the same year. Flatbed and rotary screen printing being the traditional and most widely known R2R mechanism, accounts for majority of the market revenue share. On the other hand, soft/imprint lithography mechanism is presumed to witness maximum adoption during the forecast period 2025 – 2033. The anticipated adoption of this mechanism is majorly backed by its ability to re-produce high resolution 3-D pattern on the substrate accurately. Inkjet printing is also presumed to witness strong adoption in the coming years on account of benefits offered in terms of size, weight, scalability, and non-contact printing.

As of 2021, the global roll-to-roll technology for flexible device market was led by Asia Pacific followed by North America and Europe respectively. The revenue share of Asia Pacific in the global roll-to-roll technology for flexible device market stood at 35.9% in 2021. The growth in the Asia Pacific roll-to-roll technology for flexible device market is majorly backed by growing demand for flexible electronics in countries including China, Japan, Taiwan, and South Korea. These countries are also house to large number of flexible device manufacturers who prefer R2R manufacturing over other traditional manufacturing processes due to benefits offered in terms of cost, production, and throughput. In addition, resurgence in the industrial sector coupled with increasing inflow of foreign funds is expected to support the demand for flexible electronics, and hence roll-to-roll processing instruments.

Historical & Forecast Period

This study report represents analysis of each segment from 2023 to 2033 considering 2024 as the base year. Compounded Annual Growth Rate (CAGR) for each of the respective segments estimated for the forecast period of 2025 to 2033.

The current report comprises of quantitative market estimations for each micro market for every geographical region and qualitative market analysis such as micro and macro environment analysis, market trends, competitive intelligence, segment analysis, porters five force model, top winning strategies, top investment markets, emerging trends and technological analysis, case studies, strategic conclusions and recommendations and other key market insights.

Research Methodology

The complete research study was conducted in three phases, namely: secondary research, primary research, and expert panel review. key data point that enables the estimation of Roll To Roll (R2R) Technology For Flexible Device market are as follows:

Market forecast was performed through proprietary software that analyzes various qualitative and quantitative factors. Growth rate and CAGR were estimated through intensive secondary and primary research. Data triangulation across various data points provides accuracy across various analyzed market segments in the report. Application of both top down and bottom-up approach for validation of market estimation assures logical, methodical and mathematical consistency of the quantitative data.

| ATTRIBUTE | DETAILS |

|---|---|

| Research Period | 2023-2033 |

| Base Year | 2024 |

| Forecast Period | 2025-2033 |

| Historical Year | 2023 |

| Unit | USD Million |

| Segmentation | |

Mechanism

| |

Application

| |

|

Region Segment (2023-2033; US$ Million)

|

Key questions answered in this report