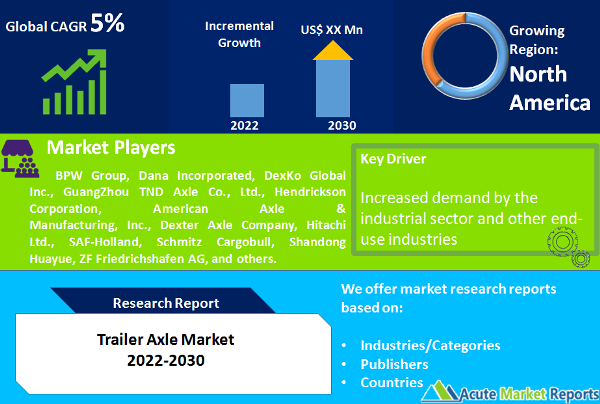

The global trailer axle market is expected to grow at a CAGR of 5% during the forecast period. An axle is a central shaft that is used for supporting the weight of the vehicle as well as moving the wheels. It is an important part of an automobile and can be divided into three distinct sorts, including the front, the rear, and the stub. The rotation of the steering wheel of the vehicle has an effect on the axle and controls its movement. It is applied in a wide variety of vehicles including automobiles, trucks, trailers, buses, and others. In addition, there are two different kinds of axles that can be found in trailers, including torsion axles and leaf spring axles. A spring is used by spring axles to provide support for both the trailer and the load. Spring axles are not very expensive and can be maintained with little effort. Torsion axles consist of a square spindle that is encased in rubber on all four sides and runs the length of the axle.

The expansion of the automotive and transportation industries, the introduction of e-axles in trailers, and the adoption of emission rules for transport refrigeration units have all contributed to the acceleration of the growth of the global market for trailer axles. However, the growth of the market is being held back by the fact that the costs of the raw materials that are used in the production of axles are often changing. In addition, an increase in the utilisation of lightweight materials in the production of axles is the element that is anticipated to present prospects for growth over the course of the projection period.

Technological Changes In The Automobile And Transportation Industries

In the last several years, the transportation and automotive industries have gone through several changes and there has been a revolutionary shift in the technologies as well. With the introduction of electric vehicles as a response to the deteriorating environment, automotive manufacturers have created e-axles, for use in both electric vehicles and trailers, depending on the application. Through the use of regenerative braking in motor vehicles, E-axles contribute to the reduction of emissions, carbon footprints, and the generation of power.

Increase In e-Commerce Across the Globe

The significant growth of e-commerce-related activities has increased the dependence of businesses involved in e-commerce on logistics service providers in the transportation industry. These providers ensure the transportation of goods through warehouses and distribution hubs, which is essential to the success of e-commerce businesses. As a result, logistics companies that provide less than truckload (LTL) and full truckload (FTL) freight shipping services are increasingly adopting trailers due to their load-carrying capacity. In addition, trailers offer the lowest cost of transportation per tonne per kilometre when compared to rigid trucks, which is further enhancing their adoption for logistics operations. As a result, the development of the automotive and transportation industries is the primary force behind the rise of the trailer axle sector.

Use Of E-Axles In Trailers Will Drive Growth In The Trailer Axle Market

Electric axles have just begun to become more commonplace in medium-and heavy-duty vehicles, in addition to trailers. The use of e-axle results in a reduction in the costs associated with maintenance, as well as lower consumption of fuel and fewer pollutants from the vehicle. An electric axle in a trailer collects the energy that is made when a trailer is rolling freely down the road and uses this to generate electric energy to charge an onboard lithium-ion battery. This is accomplished by using the energy that is created when a trailer is travelling free along the road.

Because of growing worries about the environment, automakers all around the world are putting increased emphasis on the electrification of automobiles. As a result, there has been an increase in the use of e-axles in trailers as well. E-axles are being developed and introduced by a number of different manufacturers for use in trailers in an effort to minimise carbon footprints. The kinetic energy created by the e-axle trailer's axles and wheels is converted into electricity to power the trailer. Therefore, the use of e-axles in trailers is one of the primary reasons that will drive growth in the trailer axle market

Emission Regulations for Refrigeration Units Will Drive the Trailers Market and In Turn the Trailer Axle Market

In the manufacture of chemicals or medicines, temperature-controlled environments require the use of reefer trailers. These trailers are also used for the transportation of food goods. Reefer trailers come outfitted with refrigeration units, which allow for perishable goods to maintain their quality until they are delivered to their final destination. Because the refrigeration units in a reefer trailer are required to run continuously in order to maintain the food's freshness, the trailer's overall fuel consumption is significant. As a result of this, some nations have implemented new transport refrigeration emission regulations for refrigerated units that are used in transport and that are used in trucks and trailers. The California Air Resource Board (CARB) issued guidelines for the operation of transport refrigeration units (TRU) earlier in 2023. The new regulations require the use of refrigerants with lower global warming potential as well as a transition to zero-emissions for diesel-powered tractor-trailer units (TRUs), a standard for particulate matter emissions from newly manufactured non-truck TRU engines (on trailers, domestic shipping containers, railcars, and generator set units), and the use of diesel-powered TRUs. In addition, as of the 31st of December in 2023, all newly manufactured truck TRUs, trailer TRUs, and domestic shipping container TRUs will be required to use a refrigerant with a global warming potential of less than or equal to 2,200, or to use no refrigerant at all. This requirement goes into effect.

Implementation of these new regulations for TRUs in trailers would stimulate demand for new and upgraded trailers, which will, in turn, contribute to the expansion of the market. As a result, the implementation of emission rules for transport refrigeration units is predicted to be a driving force behind the expansion of the market for trailer axles.

Growing Concern for Environment Driving Up Demand for Trailer Axles

The growing concern for the environment on a global scale is one factor that is driving up demand for trailer axles. This is because trailers with axles reduce the amount of money spent on fuel and emissions. In addition, a decrease in the costs associated with transportation, a development of the logistics sector, and an increase in the carriage capacity of trailer axles are the primary elements that contribute to an increase in sales of trailer axles in developing countries.

Automobile manufacturing businesses are being compelled to prioritise the research and development of novel lightweight materials in order to meet demands for increased fuel efficiency, decreased vehicle weight, and compliance with environmental legislation and policies. Therefore, a reduction in vehicle weight of 10 % can result in a 6% to 8% gain in fuel economy.

Because of this, companies that make axles for trailers have begun to produce them out of lightweight materials such as magnesium alloys, aluminium alloys, and glass-fibre reinforced polymer. The axle, which is constructed of lightweight material, will contribute to the reduction of vehicle weight as well as the weight of the trailer, which will, in turn, lower the amount of gasoline that the vehicle will need to use.

Expansion Of the Construction Industry Will Drive the Market for Trailer Axles

Transporting machinery, equipment, and raw materials is one of the construction industry's primary uses for trailers, which also have a wide variety of other applications in this sector. It is anticipated that one of the most significant forces that would assist in the expansion of the trailer axle market will be the increasing production of the construction industry. With the exponential growth of the construction sector, there is a huge potential for manufacturers of trailers and, consequently, trailer axles. Within the construction industry, a high load-bearing capacity that is also conducive to transportation will continue to be the most significant element driving the need for trailer axles.

Trailer Axle Market Is Set to Register a Good Growth

In addition, because there is a growing need for automobiles that use less fuel, the leading market participants are anticipated to be able to supply items that are inexpensive, fuel-efficient, and lightweight. It is anticipated that the development of lightweight materials for axle construction, such as magnesium, aluminium, steel, and glass fibre-reinforced polymer (GFRP), will fuel the expansion of the market. This represents a significant opportunity for companies that manufacture trailers and, by extension, trailer axle manufacturers. Because of their great load-bearing ability, which makes transportation easier, trailer axles will continue to be in high demand in the construction industry. This will be the key factor affecting demand for trailer axles. It is anticipated that building and urbanisation would have a moderate impact on the market for trailer axles over the course of the forecast period.

Multi-Axle Trailer Held the Biggest Market Share

The multi-axle trailer held the biggest revenue share in 2021. It is capable of loading over-dimension cargo (ODC) thanks to the installation of axle lines that may be adjusted according to need. Because the axle lines of a multi-axle trailer may be attached and detached, the trailer can be utilised for a variety of purposes. Starting at 15 tonnes of payload capacity can be carried by each axle line. Additionally, it provides the utmost agility, excellent stability and mobility, as well as safety.

Aftermarket Services for Axle Replacement and Maintenance Presents a Good Opportunity for The Axle Market

There is a concerted effort being made by governments all over the world to promote the use of electric vehicles and hybrid vehicles. As a result, it is projected that an increasing preference for electric vehicles and hybrid vehicles will propel market expansion. In addition, the car industry is working to build technologically sophisticated axles that are lighter, smaller, and more efficient in terms of both fuel consumption and performance. The implementation of technical innovation has resulted in an increase in the adoption of lightweight axles, which provide increased efficiency and contribute to lowering the overall weight of hybrid, electric, and commercial vehicles, encouraging the growth of the market. Additionally, new business opportunities are being created by aftermarket services, which include the maintenance and replacement of axles in powertrains.

North America Is the Leader in The Trailer Axle Market

North America led the global market for trailer axle in terms of revenues. The significant demand for tractor-trailer trucks in nations such as the United States is one of the primary driving forces behind the economic expansion in this region. In addition to this, the popularity of the vehicle market as a whole is another factor that promotes demand for the product in this region. In the meantime, it is anticipated that the Asia-Pacific region would experience sizeable expansion in the global market for trailer axles. It is anticipated that highly industrialised countries like India and China will lead to an increase in the demand for trailer trucks to transport commodities. Because of this, demand will increase in the global market for trailer axles.

Cost Remains the Key Concern of Market Players

Cost consciousness and rising operational expenses are compelling manufacturers to cut production, maintenance, and repair costs, which are greater for conventional and older versions of trailer axles. This is because conventional and older versions of trailer axles are more expensive. Axles are notoriously difficult to manipulate and keep in good working order due to the intricacy of their braking and suspension systems. Aside from that, they require a significant amount of upkeep, which includes but is not limited to routine lubrication. The expenses associated with manufacturing and installation of a trailer axle change depending on the potential applications for the axle. The use of greater resources and raw materials is necessary for customised trailer applications. The cost of a customised trailer axle is higher than the cost of a conventional trailer axle. This is because the cost of the inputs is higher. Because they assist cut down on both the prices and the amount of time needed for transportation, as well as enhancing the load-carrying capacity of the entire system, manufacturers are under constant pressure to improve the trailer axles that they produce. Because of this, manufacturers strive to develop trailer axles that have better efficiency, are simple to maintain, and ultimately provide operators with solutions that are more cost-effective. The report on the global trailer axle market includes an analysis of the major market players, such as BPW Group, Dana Incorporated, DexKo Global Inc., GuangZhou TND Axle Co., Ltd., Hendrickson Corporation, American Axle & Manufacturing, Inc., Dexter Axle Company, Hitachi Ltd., SAF-Holland, Schmitz Cargobull, Shandong Huayue, ZF Friedrichshafen AG, In order to compete, these market participants have implemented a variety of strategies, such as joint ventures, partnerships, expansion, and collaboration, to enhance their market shares.

Historical & Forecast Period

This study report represents analysis of each segment from 2022 to 2032 considering 2023 as the base year. Compounded Annual Growth Rate (CAGR) for each of the respective segments estimated for the forecast period of 2024 to 2032.

The current report comprises of quantitative market estimations for each micro market for every geographical region and qualitative market analysis such as micro and macro environment analysis, market trends, competitive intelligence, segment analysis, porters five force model, top winning strategies, top investment markets, emerging trends and technological analysis, case studies, strategic conclusions and recommendations and other key market insights.

Research Methodology

The complete research study was conducted in three phases, namely: secondary research, primary research, and expert panel review. key data point that enables the estimation of Trailer Axle market are as follows:

Market forecast was performed through proprietary software that analyzes various qualitative and quantitative factors. Growth rate and CAGR were estimated through intensive secondary and primary research. Data triangulation across various data points provides accuracy across various analyzed market segments in the report. Application of both top down and bottom-up approach for validation of market estimation assures logical, methodical and mathematical consistency of the quantitative data.

| ATTRIBUTE | DETAILS |

|---|---|

| Research Period | 2022-2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Year | 2022 |

| Unit | USD Million |

| Segmentation | |

Type

| |

Axel Type

| |

Capacity

| |

Application

| |

Sales Channel

| |

|

Region Segment (2022-2032; US$ Million)

|

Key questions answered in this report